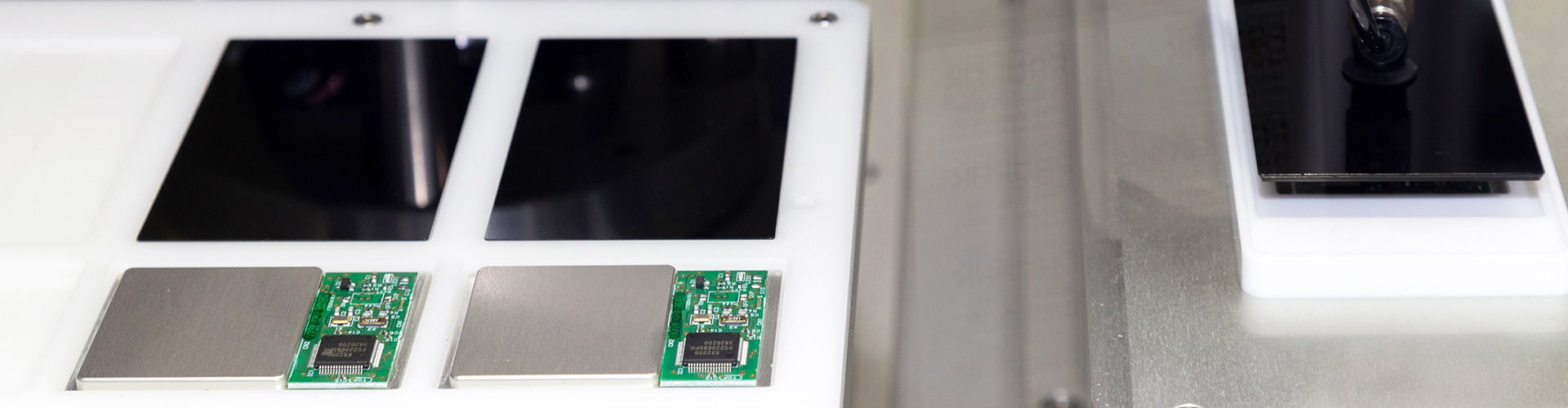

The function of FOG binding is to directly bond the flexible circuit board or ribbon cable onto the electrode at the edge of the liquid crystal glass. The process of installing cables and flexible circuit boards on LCD glass. The quality of FOG binding process directly affects the production yield and service life of LCD screens.

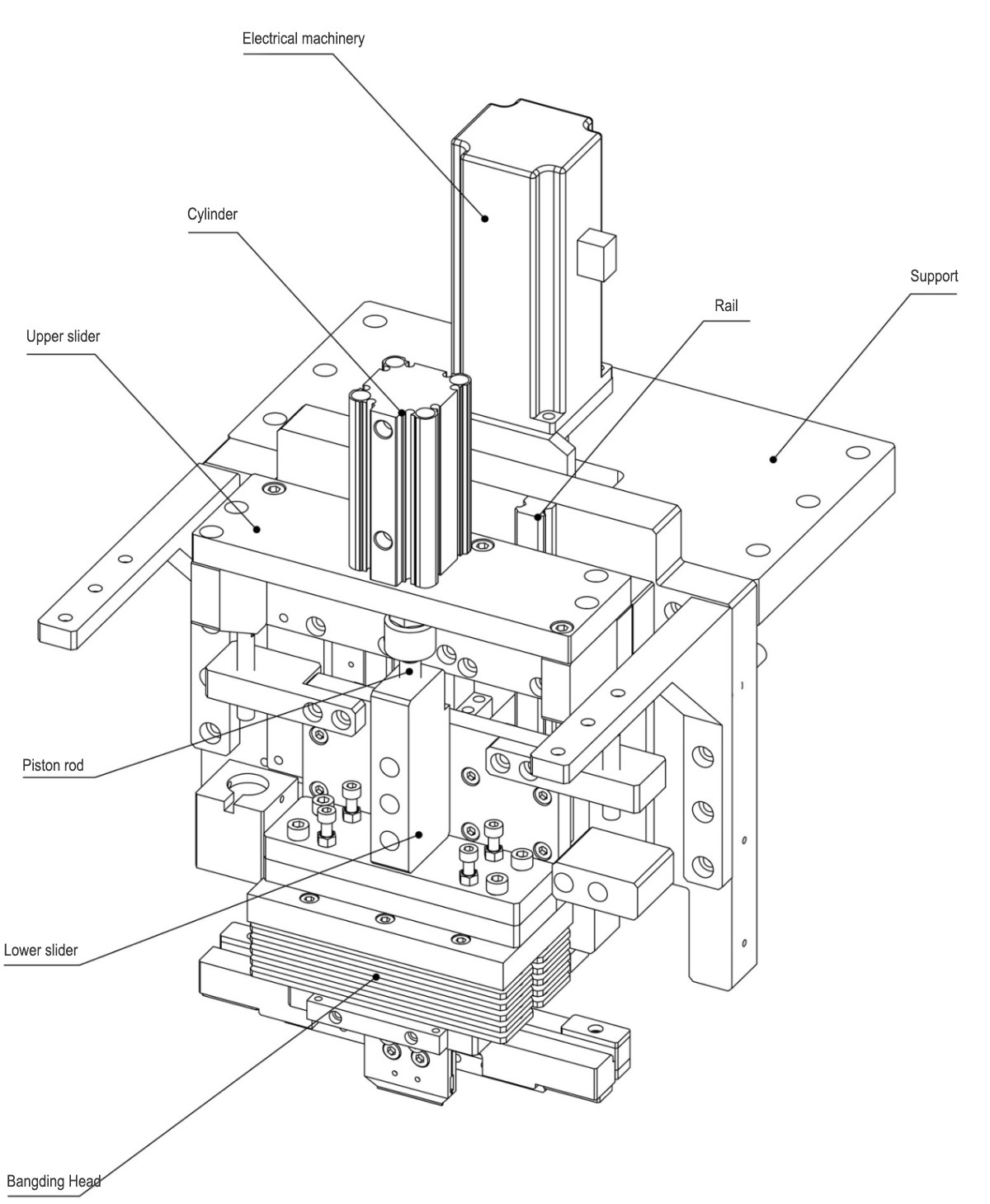

The core part of the bonding machine consists of a bracket, motor, guide rail, screw rod, screw nut, upper slider, and slide

The main components include blocks, cylinders, bonding heads, solenoid valves, electrical proportional valves, controllers, etc.

Technical parameters:1. Air source pressure: 0.5~0.7MPa

2. Binding pressure: 3~40Kgf

3. Pressure accuracy: ± 0.2Kgf

4. Binding temperature: RT~499 ℃

5. Hot pressing time: 1-99 S

6. Hot pressing accuracy: 0.14mm

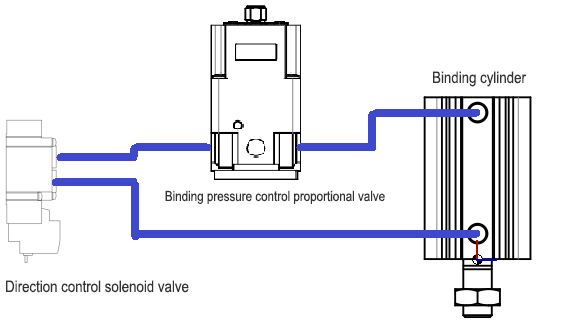

1. When the device is in standby mode, the solenoid valve controls the cylinder to rise, and the proportional valve is in the exhaust state

2. During operation, the solenoid valve controls the descent of the cylinder, while the proportional valve controls the pressure when the cylinder descends. Real time pressure adjustment can be made based on the binding process compared to the example valve.

Advantage:Pressure control, the size of binding pressure directly determines the degree of fragmentation of ACF conductive particles, thereby determining the production yield of LCD screens. Therefore, precise control of binding pressure during the binding process is very important. If the binding pressure is too small, the normal fragmentation of ACF conductive particles cannot be achieved, thereby affecting the longitudinal electrical conductivity performance. Causing longitudinal electrical failure to conduct. If the binding pressure is too high, it will cause ACF conductive particles to be crushed too much, thereby affecting the horizontal electrical insulation effect.

After using the NITV electrical proportional valve, the binding pressure of the FPG binding machine can be directly controlled by the PLC control system, so that the degree of fragmentation of ACF conductive particles can be directly controlled by the program.

By using the NITV electrical proportional valve, multiple heating pressure binding can be achieved, and each binding temperature and binding pressure can be independently set;

Driven by the NITV proportional valve, the binding cylinder allows for precise pressure adjustment, higher accuracy, and stable binding pressure;

Digital Vacuum Pressure Regulator NITV2090

Digital Vacuum Pressure Regulator NITV2090  Electric Pneumatic Regulator NITV1000

Electric Pneumatic Regulator NITV1000  Digital Pressure Sensor 10A(F)

Digital Pressure Sensor 10A(F)  Digital Pressure Sensor 70/75/75H

Digital Pressure Sensor 70/75/75H  Digital Pressure Sensor 40A(F)

Digital Pressure Sensor 40A(F)  Digital Pressure Sensor 80A(F)

Digital Pressure Sensor 80A(F)  Low Profile Air Gripper NMHF2

Low Profile Air Gripper NMHF2  Parallel Type Air Gripper NMHZ2

Parallel Type Air Gripper NMHZ2  Rotary Table/Rack & Pinion Type NMSQ

Rotary Table/Rack & Pinion Type NMSQ  180° Reversing clamping cylinder NRML

180° Reversing clamping cylinder NRML